Ramjet Engine, Design and Combustion Optimization (SR-71 Blackbird), Industrial Application

۱۰,۵۳۰,۰۰۰ تومان تخفیف دانشجویی

- In this project, an industrial Ramjet Engine has been numerically simulated by ANSYS Fluent software.

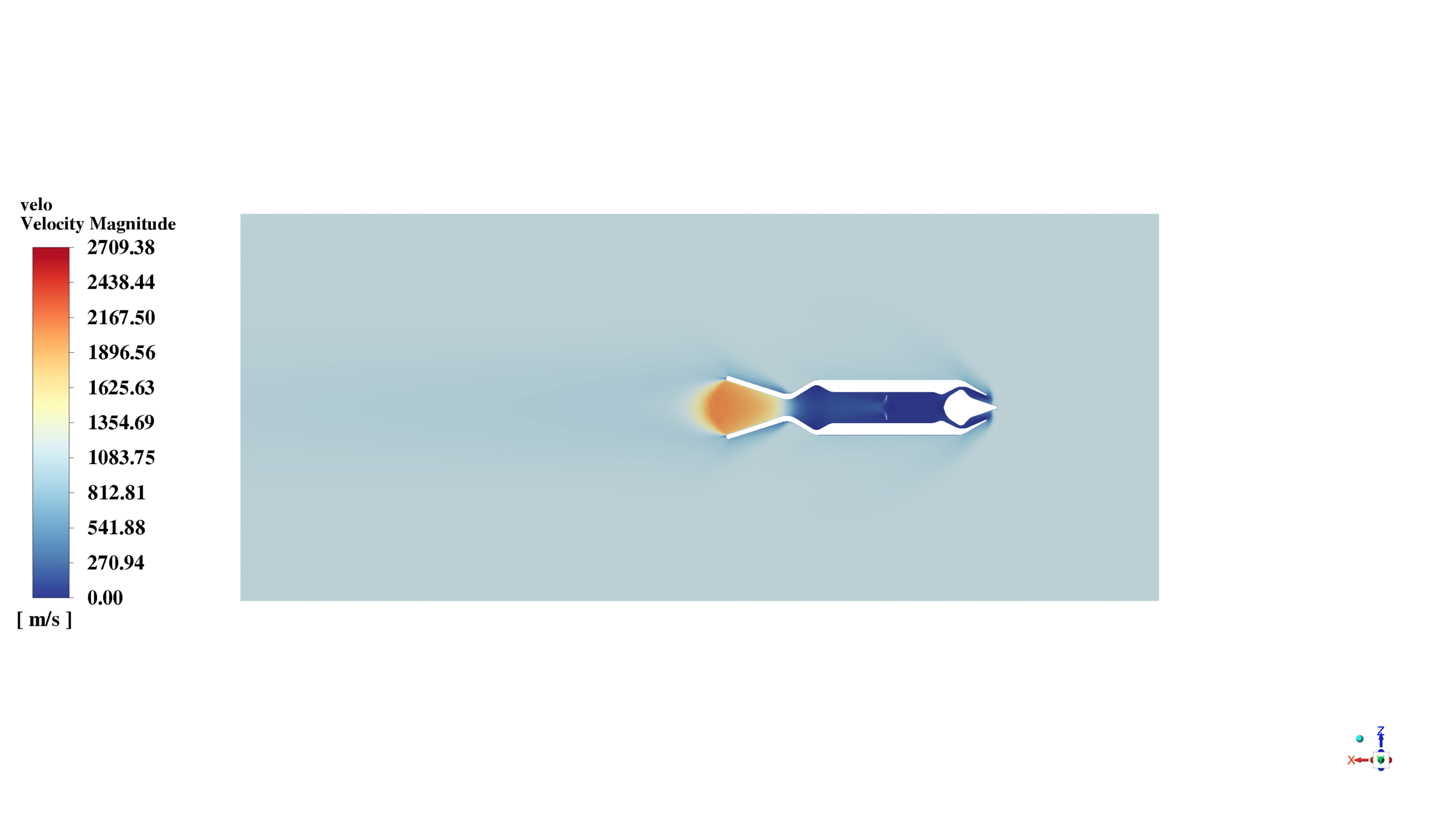

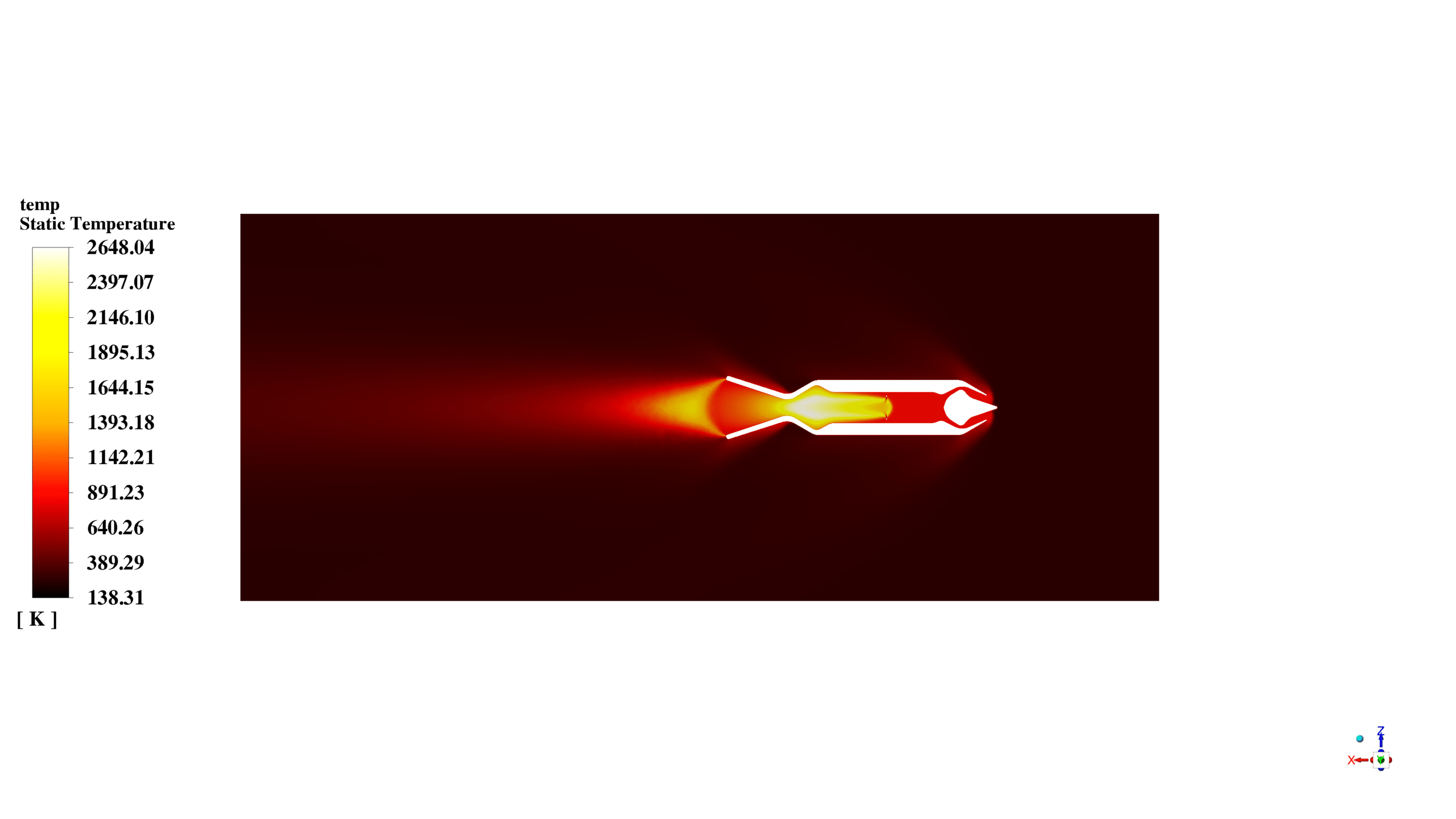

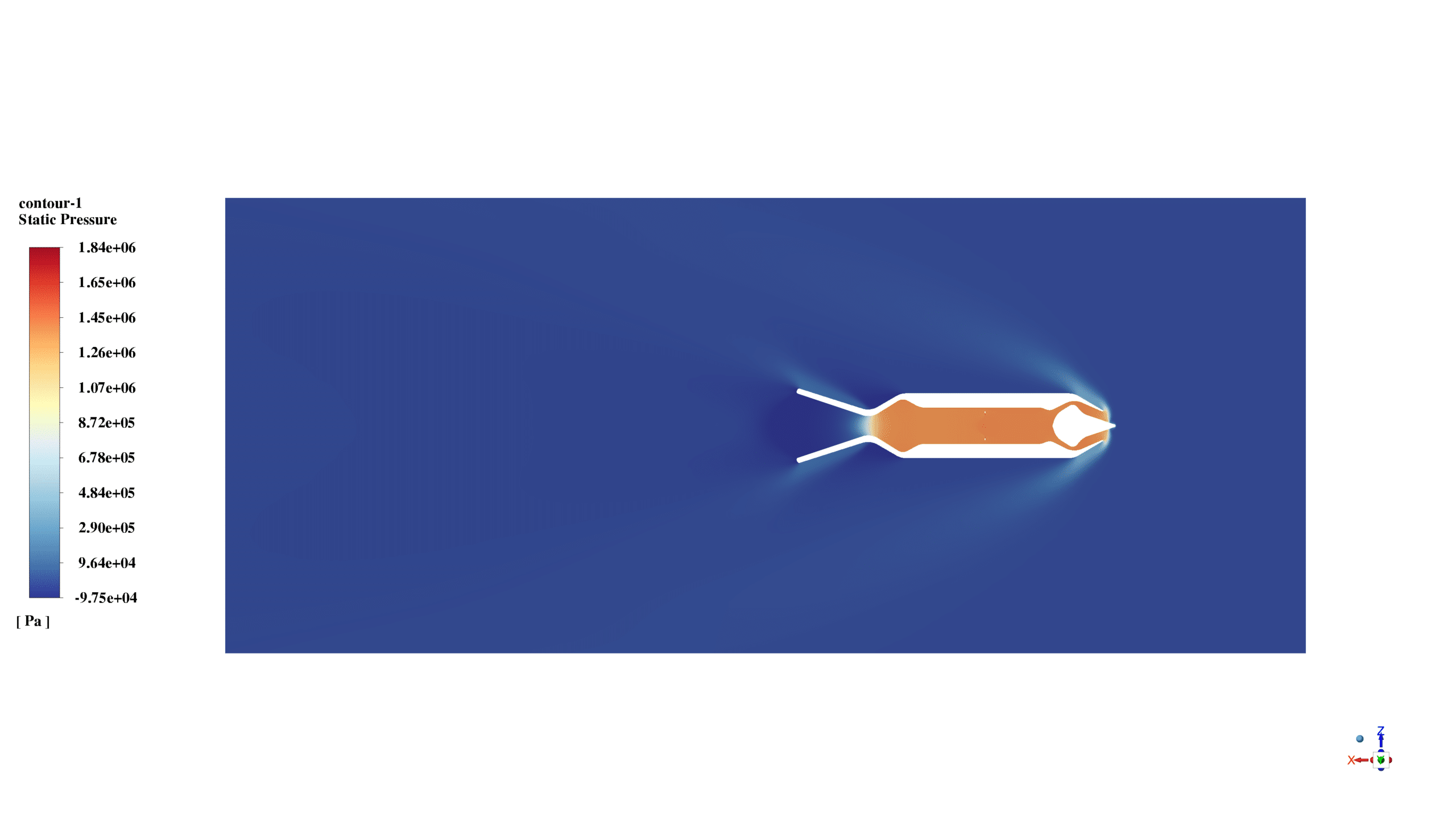

- Studying Combustion, Mach Number, Pressure, Density (Compressible Flow), and Thermal analysis.

- Optimizing the Thrust number.

- Ramjet Design Improvement.

- RSM analysis applying DOE.

بر روی افزودن به سبد خرید کلید کرده و فایل های هندسه، مش و فیلم آموزشی جامع را دریافت کنید.

برای سفارش پروژه خود و یا بهره مندی از مشاوره رایگان، با کارشناسان ما از طریق ایمیل ([email protected])، پشتیبانی آنلاین و یا واتس اپ (09126238673) در ارتباط باشید.

برای کنترل کیفیت خدمات ما میتوانید از محصولات رایگان استفاده کنید.

توضیحات

Introduction

An air-breathing jet engine, known as a ramjet, compresses incoming air instead of utilizing a rotary compressor by moving the engine forward. A ramjet cannot operate at zero airspeeds; hence it cannot be utilized to power an aircraft throughout all phases of flight. A ramjet-equipped aircraft needs additional propulsion to accelerate it to a speed where the ramjet can provide thrust.

In the combustor of a ramjet, combustion that generates thrust happens at a subsonic speed. The aircraft inlet must slow the air entering the engine for a vehicle operating at supersonic speeds. The propulsion system suffers performance losses due to shock waves in the inlet. Ramjet propulsion is relatively inefficient over Mach 5.

In this situation, fuel is crucial. When considering other beneficial factors, such as the fact that the air’s overall Temperature is high at high Mach numbers, hydrogen is especially advantageous due to its well-known relatively short inflammatory delay.

Project Description

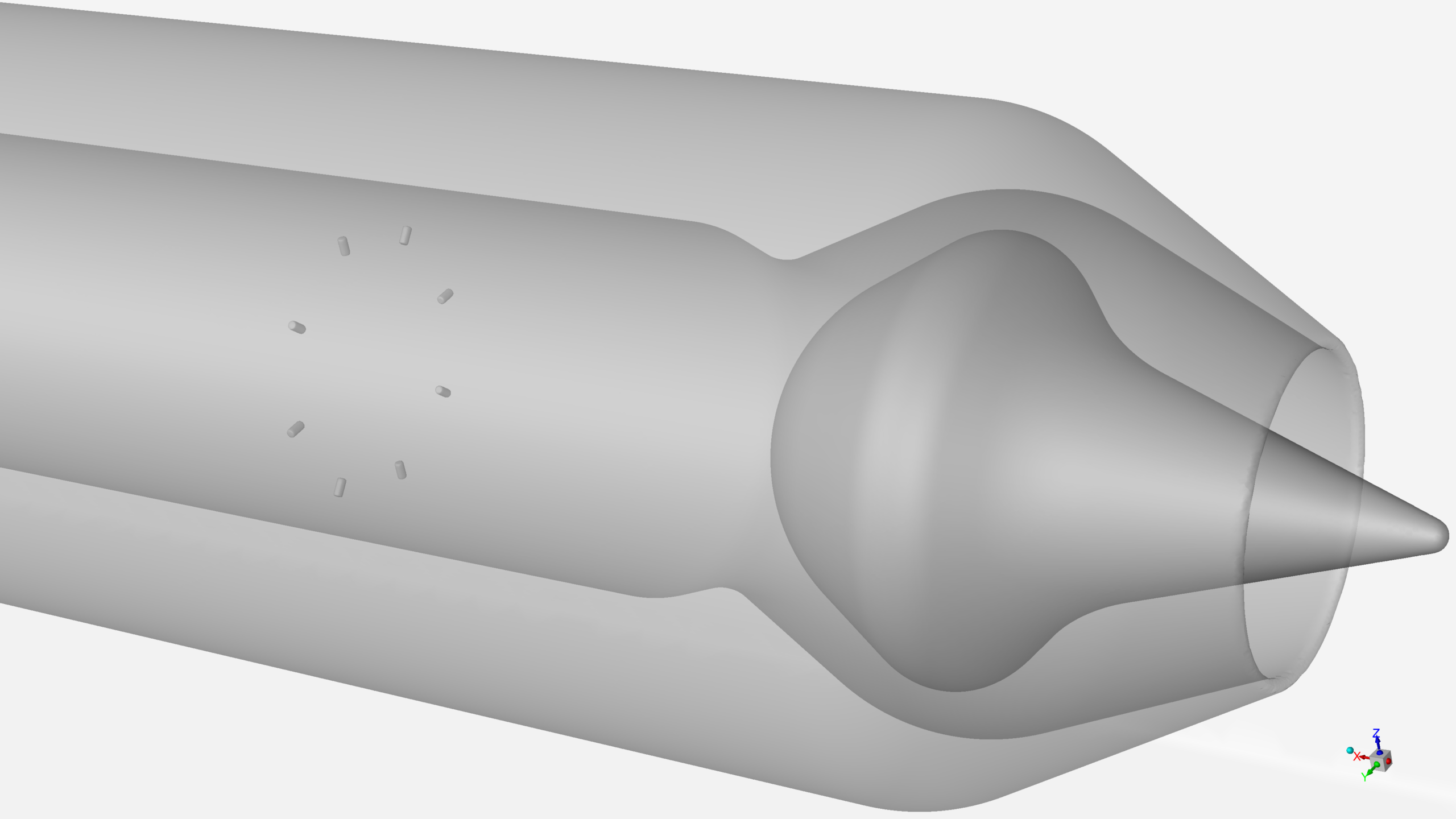

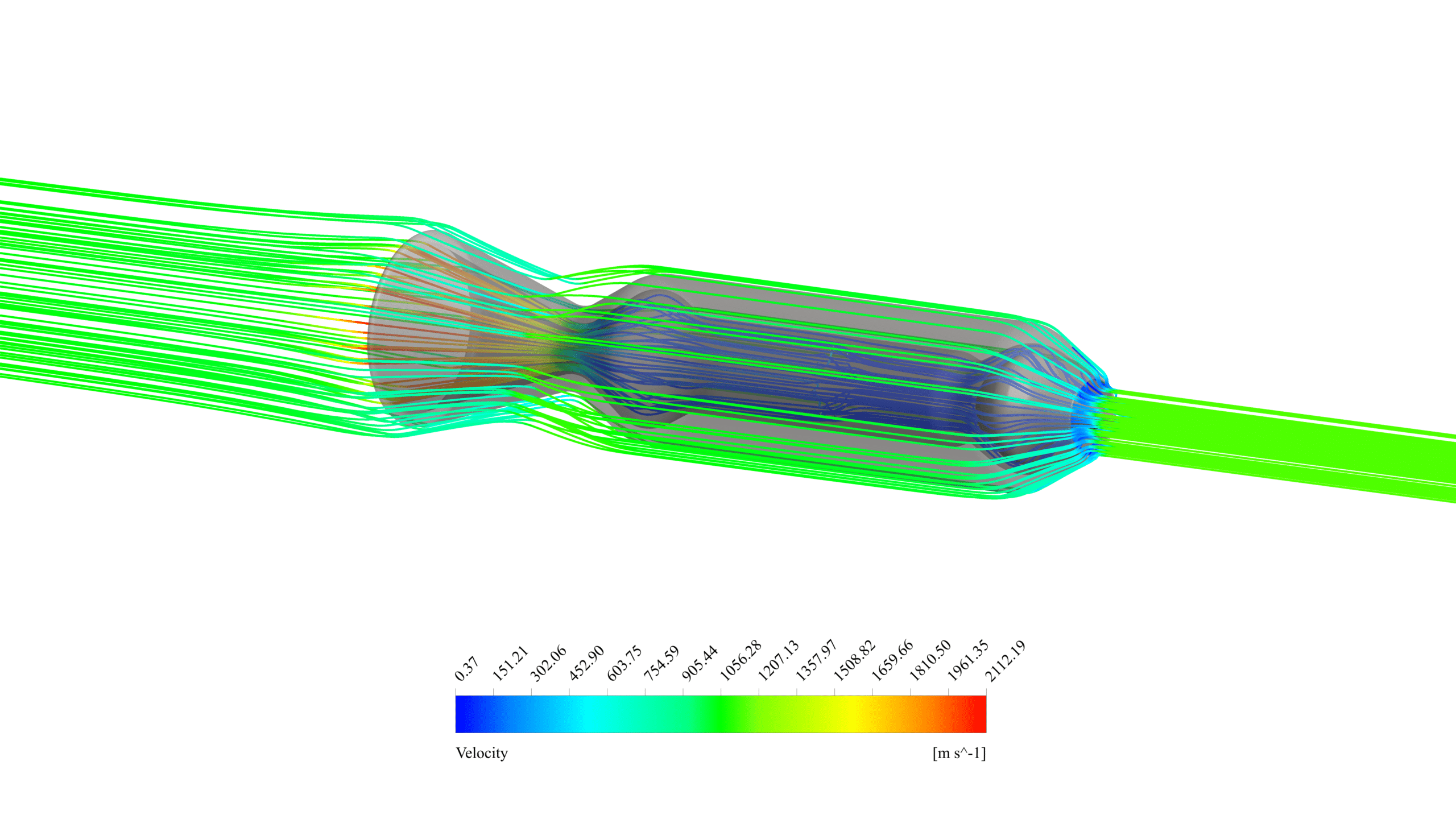

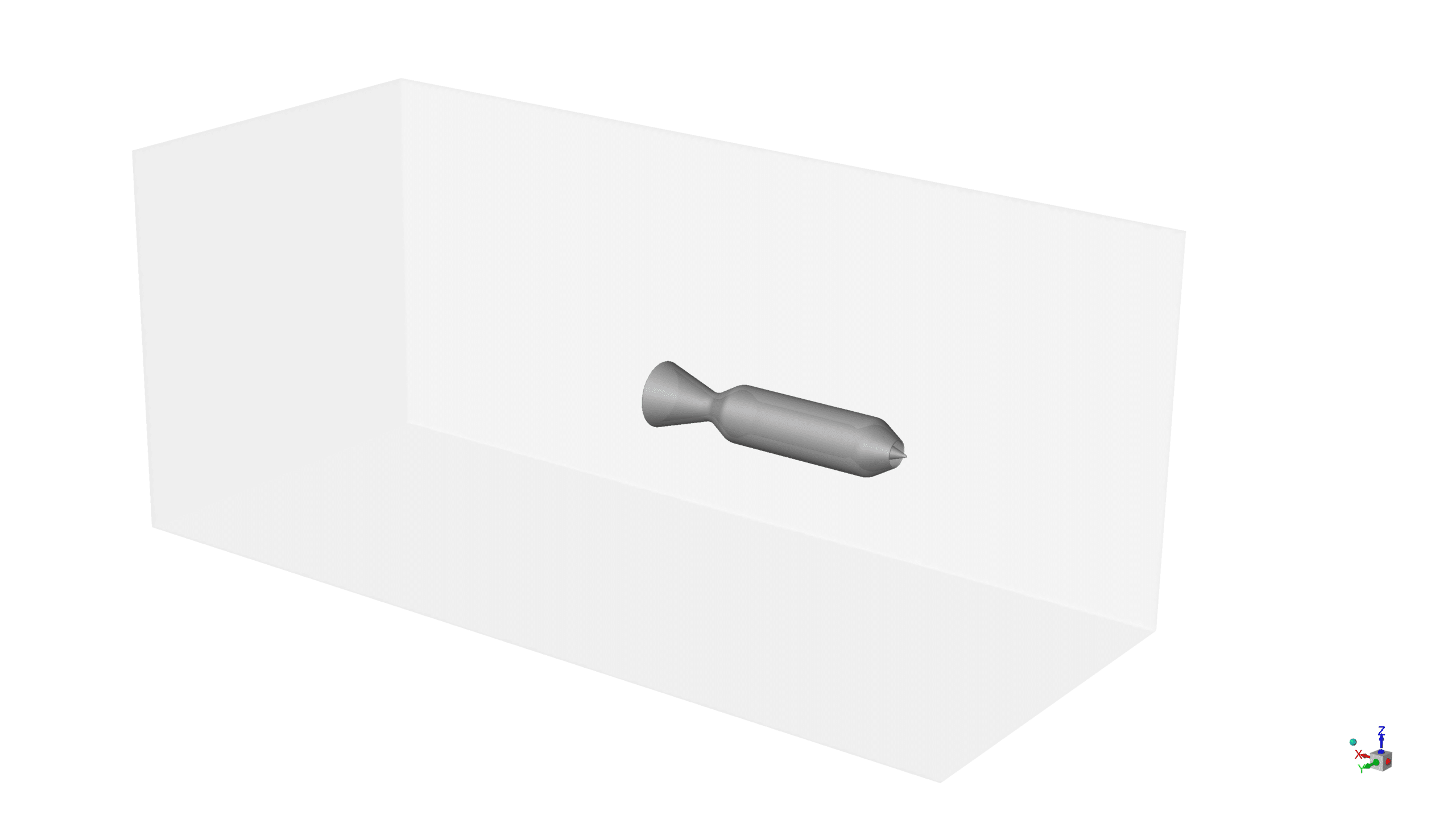

In this simulation, an SR-71 Black Bird moving with a Mach number of 3.3 is considered. The point is to model the ramjet engine to capture what happens there and investigate the parameters.

In the next step, 3 crucial parameters are selected, and the solution is optimized using the DOE method in ANSYS Workbench software.

-

Ramjet CFD Simulation

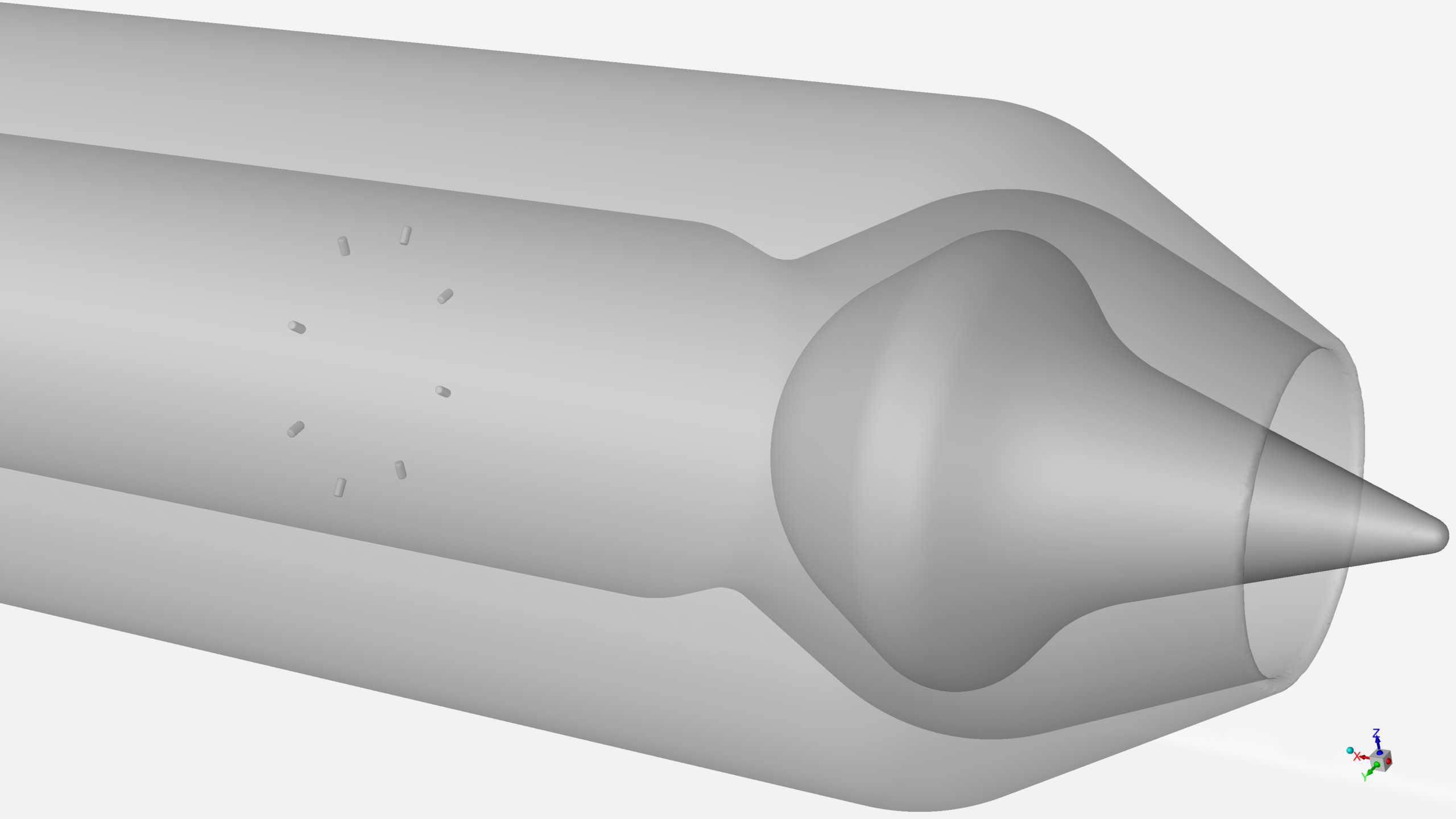

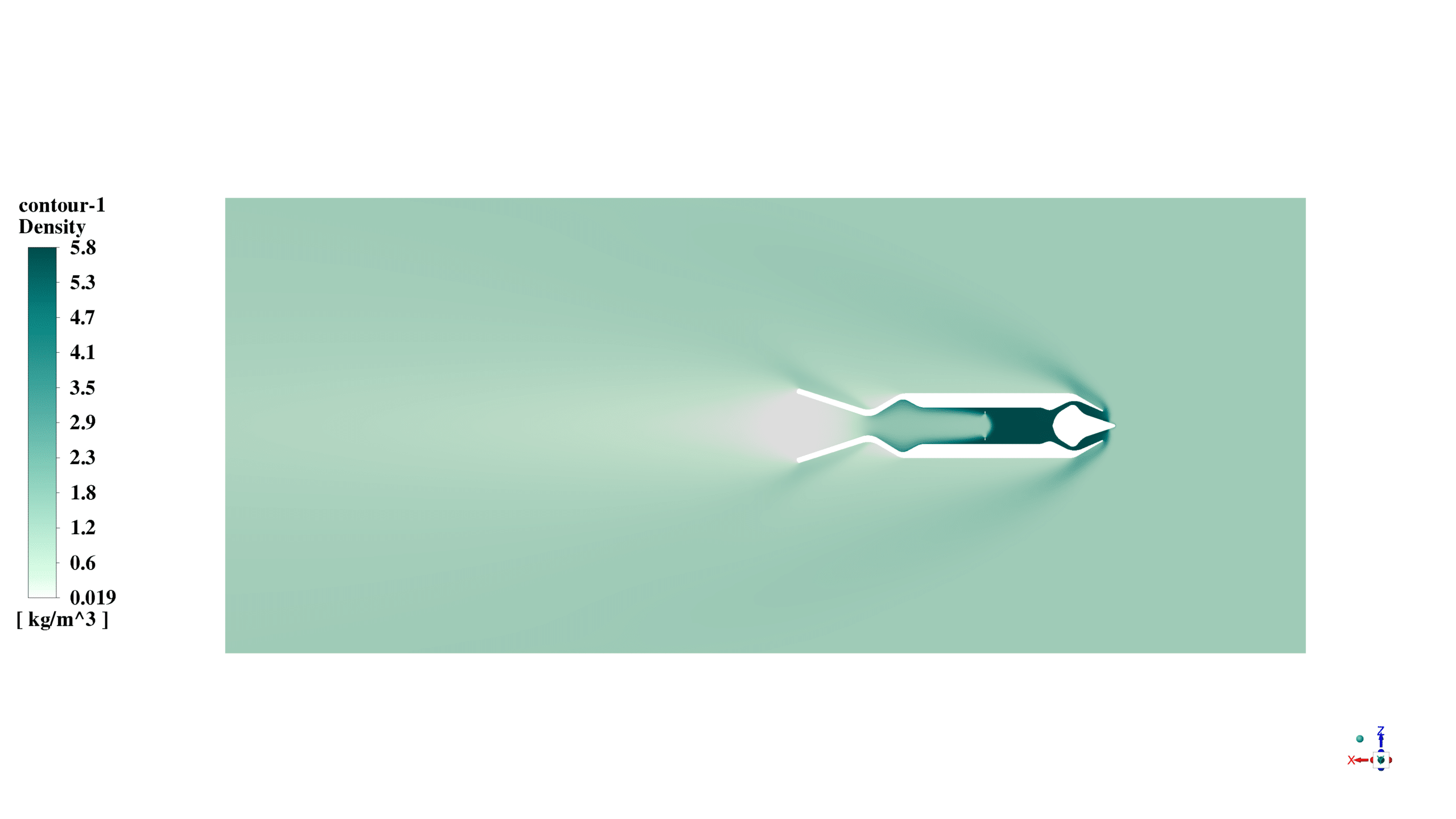

As mentioned above, the first step is to simulate the engine of the SR-71 Black Bird, which is a ramjet engine without any moving object inside. The jet is moving with a Mach number of 3.3. There is an injection slot inside the chamber at a distance of 70 cm from the chamber inlet. The fuel, which is hydrogen, is injected into the engine with a mass flow rate ratio of 1 to 50 relevant to the air. Notably, the injection angle is 0 degrees, meaning the fuel is injected perpendicular to the airflow.

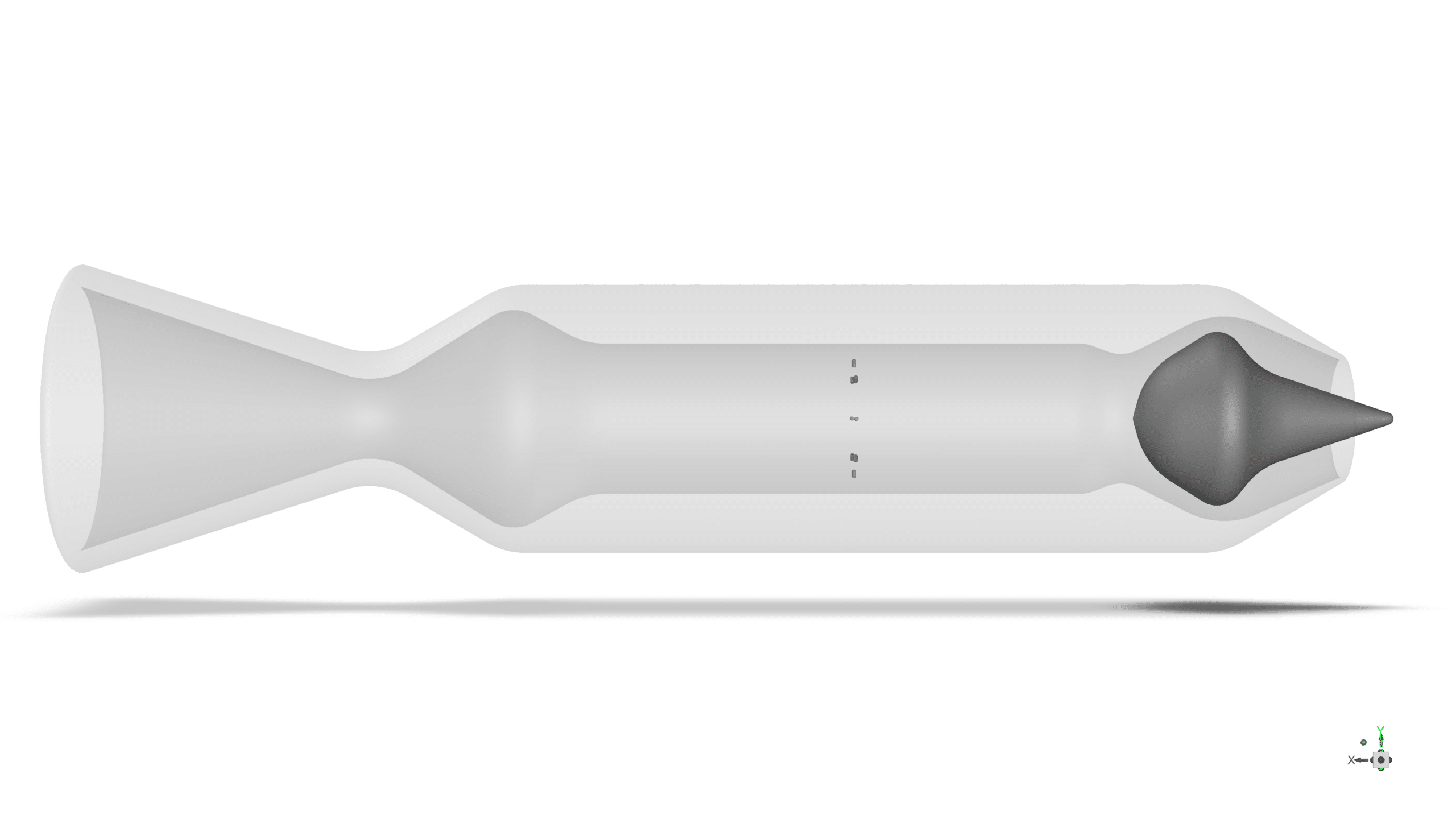

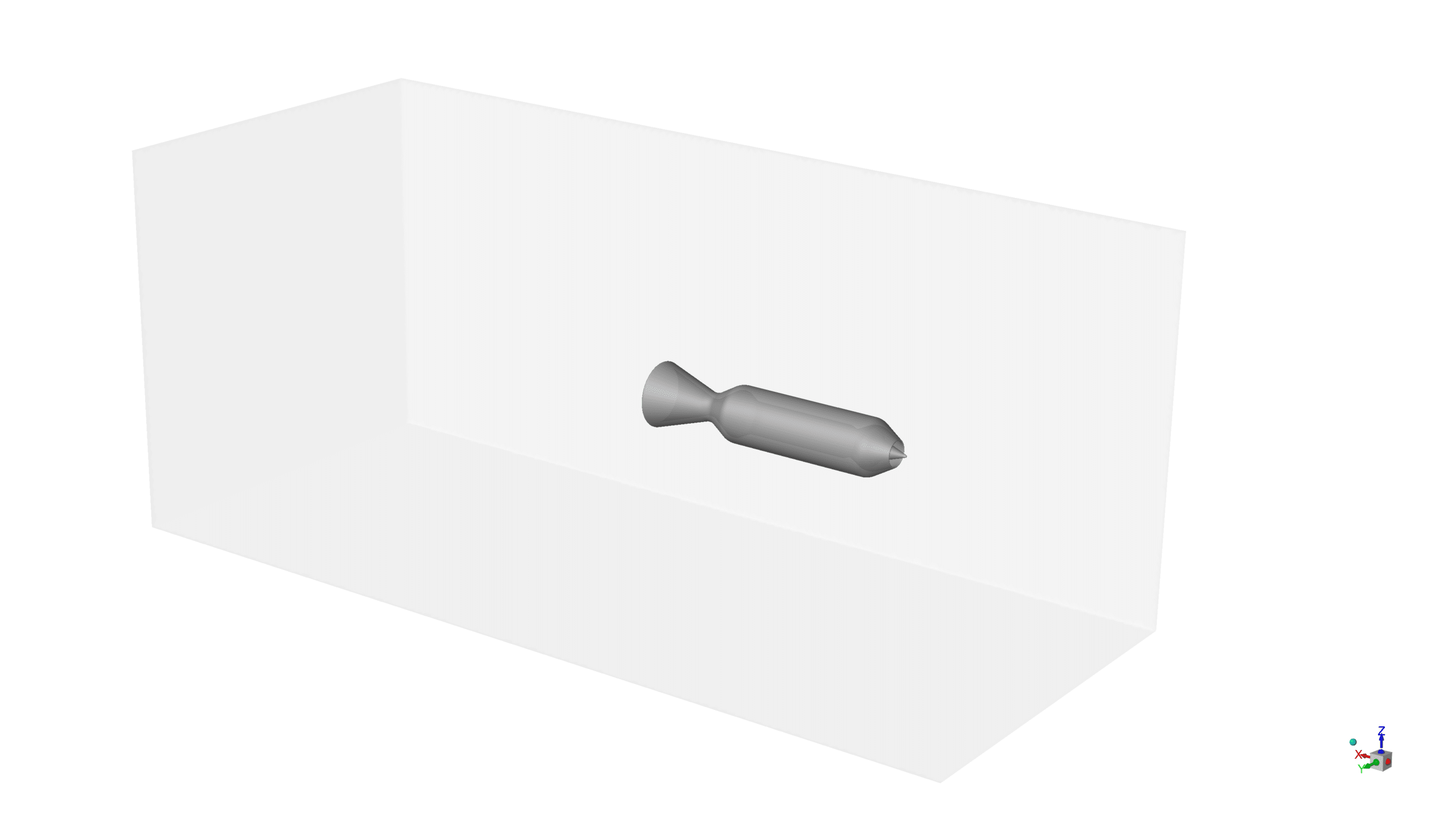

The model of the ramjet engine and the solution results are visible in the following figures, considering different significant parameters for us.

-

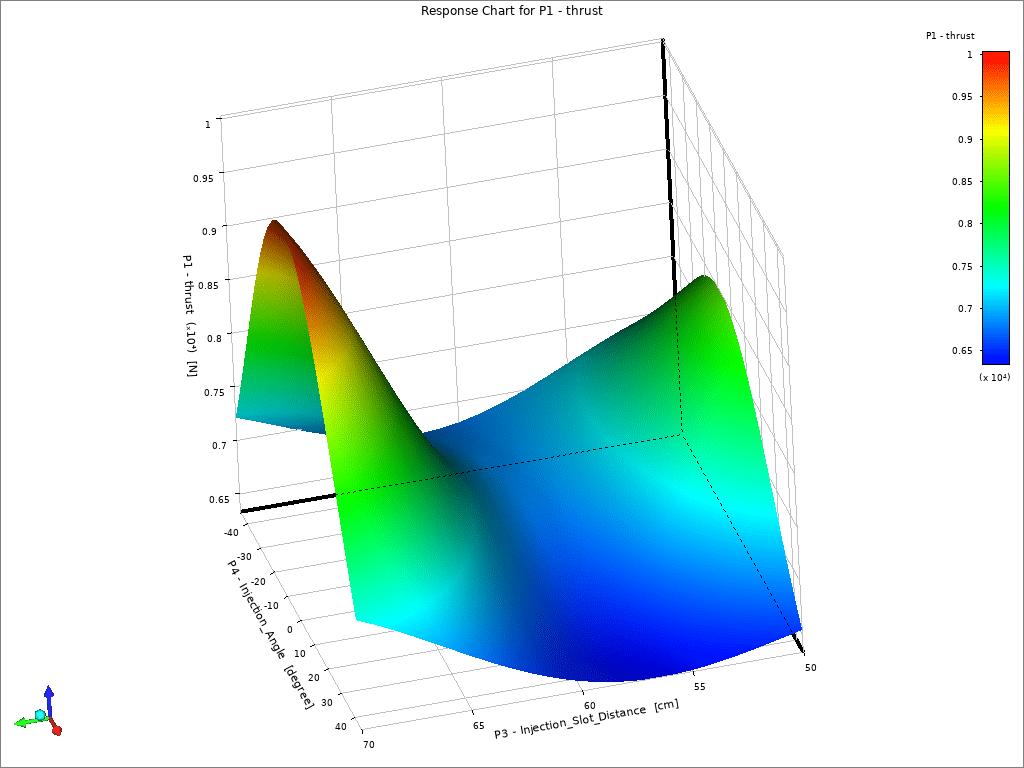

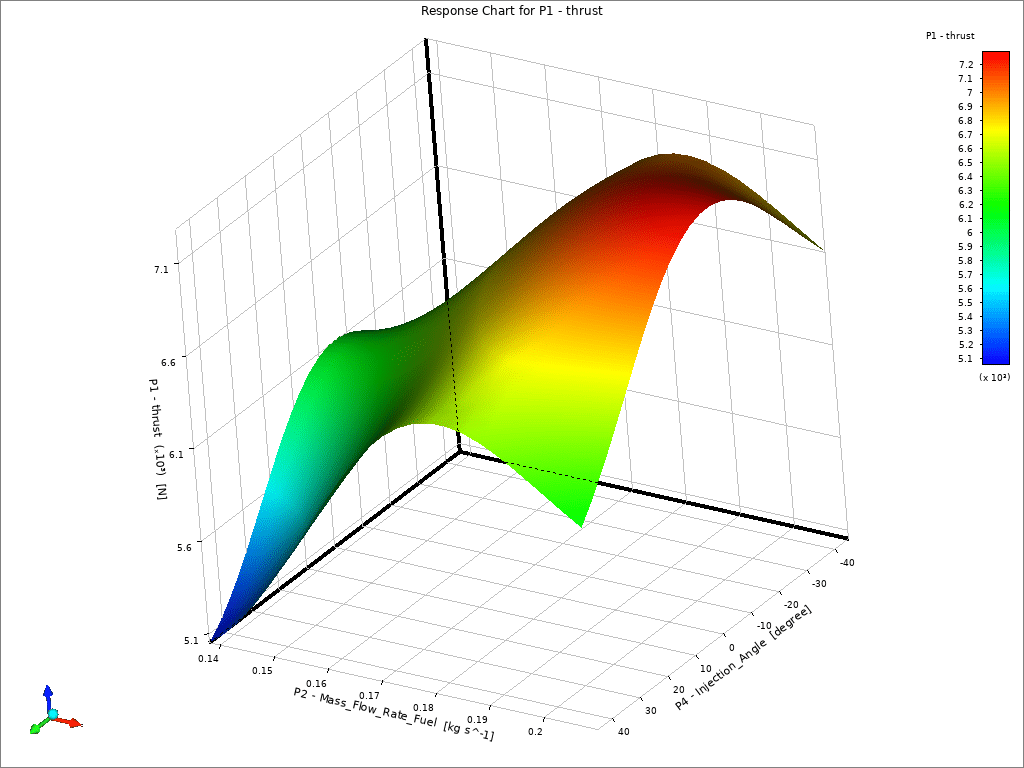

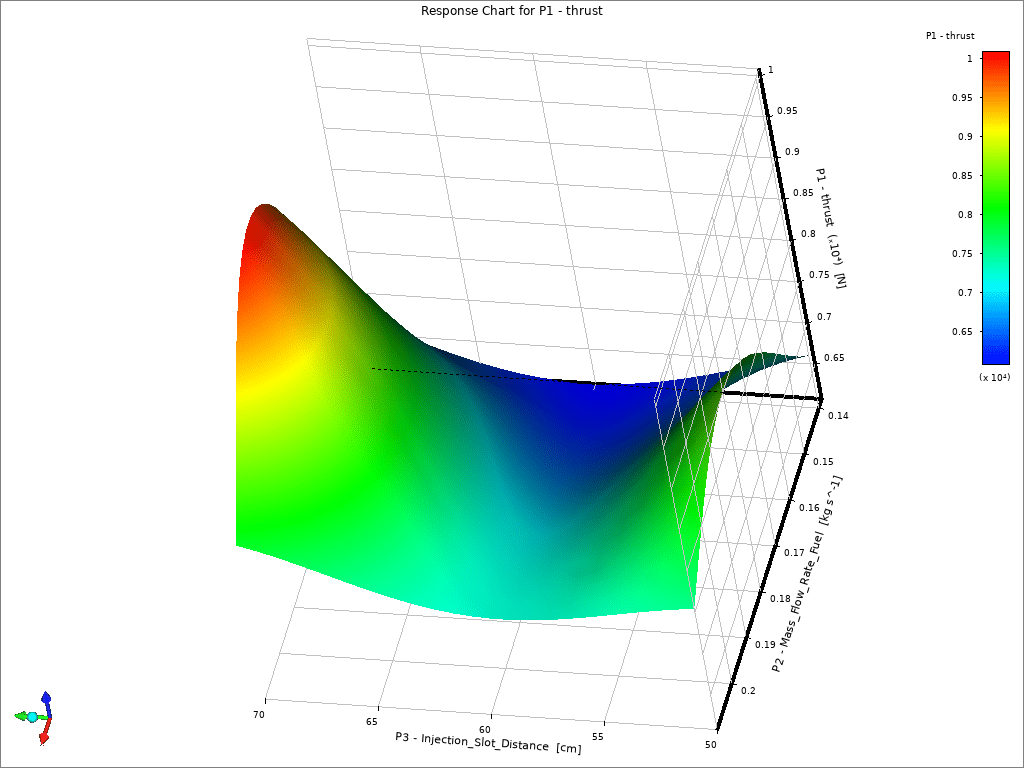

Optimization

In order to optimize the device performance and to get the maximum use of fuel and consequently the highest thrust number, the Design of Experiment study is carried out on the solution. 3 parameters that affect the results drastically are chosen to examine the effects of their changes. The parameters are as follows:

- Fuel mass Flow rate

- Injection angle

- The distance of the injection slot from the engine inlet

In the first simulation discussed above, parameters 1, 2 and 3 are 0.17 kg/s and 60 cm, respectively.

The optimization case has studied parameters 1 to 3 in the following range:

- 138 kg/s – 0.21 kg/s

- (-45) – (45) Degrees (Negative in opposite and positive in the direction of the airflow)

- 50 cm – 70 cm

Finally, 3D plots of the parameters and their effect on the thrust of the ramjet are achieved.

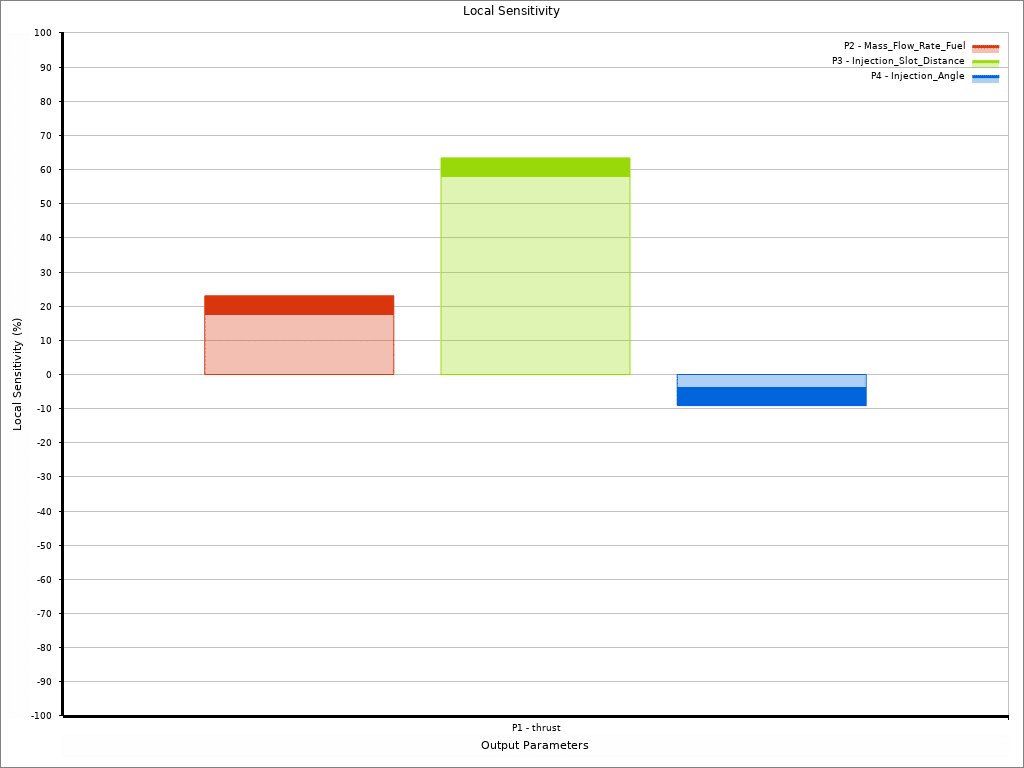

Also, the Local Sensitivity bars show the sensitivity of the output, which here is the thrust number, to each defined parameter:

The DOE model also gave us the minimum and maximum amount of the parameters considering their interactions. The highest and lowest amount of the thrust in the carried out simulation would achieve in the following settings:

The highest Thrust number:

- Fuel mass Flow rate 0.1784 kg/s

- Injection angle 70 cm

- The distance of the injection slot from the engine inlet +0.6568 degrees

The lowest Thrust number:

- Fuel mass Flow rate 0.138 kg/s

- Injection angle 65.994 cm

- The distance of the injection slot from the engine inlet +45 degrees

دیدگاهها

هیچ دیدگاهی برای این محصول نوشته نشده است.